3D printing

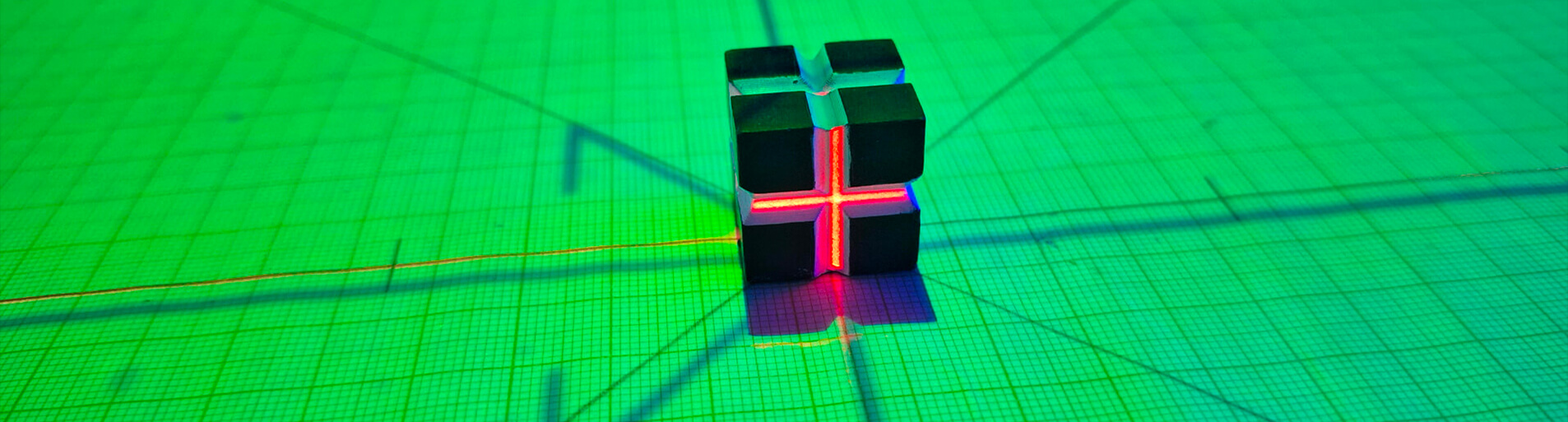

3D printing stands as one of the greatest game changers of the past decade. Its utilization in the medical field has materialized theoretical concepts into tangible objects, responsible for innovations that enhance the quality of patient care. Within the Medical Physics Lab, our 3D printing platform enables us to tackle complex medical challenges, offering concrete solutions for each issue. Our activities include the creation of accurate anatomical models for (pre)clinical research, the personalization of medical devices to meet individual patient specifications, as well as the development of new healthcare solutions for previously abstract problems. The fields of application in which we are involved are numerous, ranging from diagnostics to therapy and healthcare professional training.

If you have an idea, feel free to contact us to discuss how we can bring it to life!

A selection of our projects:

A selection of our projects:

- Personalized silicon external prosthesis

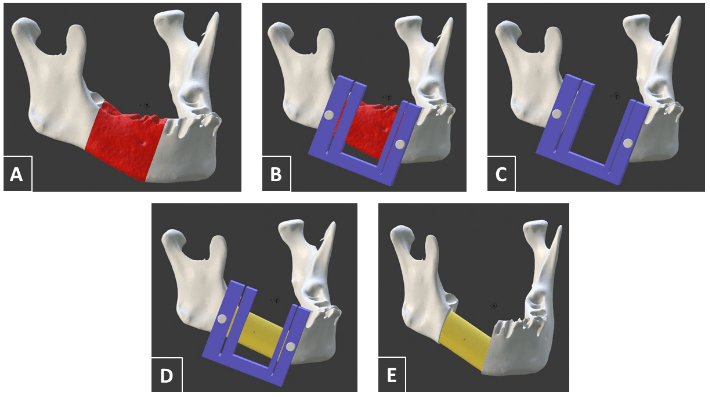

- Development of new cutting guides for surgical resection of bone tumors